- Home

- How To Do It . . .

- Build A Screen Room

- Screening Your Enclosure

Screening Your Enclosure

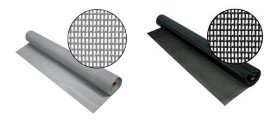

Screening Material

18 x 14 Phiferglass© fiberglass screening is used to screen in your enclosure. Woven from permanent glass yarn which has been coated with a protective vinyl to ensure lasting beauty, color and flexibility. Phiferglass© is noncombustible and will not rust, corrode or stain. Lightweight and economical, Phiferglass© comes in several different weaves using different thread diameters. The 18 x 14 weave is designed for the aluminum extrusion system used to build your screen room. It is a stronger mesh recommended for larger openings where added strength is desirable. It is made with .013" Diameter threads with 18 threads per inch vertically and 14 threads per inch horizontally.

18 x 14 Phiferglass© fiberglass screening is used to screen in your enclosure. Woven from permanent glass yarn which has been coated with a protective vinyl to ensure lasting beauty, color and flexibility. Phiferglass© is noncombustible and will not rust, corrode or stain. Lightweight and economical, Phiferglass© comes in several different weaves using different thread diameters. The 18 x 14 weave is designed for the aluminum extrusion system used to build your screen room. It is a stronger mesh recommended for larger openings where added strength is desirable. It is made with .013" Diameter threads with 18 threads per inch vertically and 14 threads per inch horizontally.

Colors Available : Black or Gray Colors.

Widths available : 36", 48", 60", 72" and 96"

Roll Sizes : 100 foot or 25 foot

The width used must be at least 4" wider than the width of your largest opening.

For More Information On Fiberglass Screening

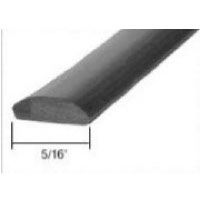

1/4" Flat Spline

1/4" Flat Spline

The Aluminum extrusion has Spline Groove that is designed for a flat spline. The spline locks the screening in place. Always insert the spline to the inside of the Spline Channel and roll to the outside of the Spline Channel to avoid cutting the fiberglass screening.

Screening : Side 1

Screening : Side 1

Begin screening about 1" or 2" below the top of one horizontal side. Overlap the Spline Groove by about 1/8" with the screening. Insert the flat spline. Allow enough spline to reach to about 1/4" from the top. Holding the spline in place, roll the spline into the Spline Groove. As you roll, try to keep your overlap to 1/8". It is important that the screening on the first side rolled be relatively straight. When you get about 2" from the end of the Spline Channel, cut the spline about 1/4" short of the end of the Spline Channel.

Screening : Side 2

Begin screening about 1" or 2" below the top of opposite horizontal side. Pull the screening across the spline channel. Insert the spline to the inside of Spline Groove. Allow enough spline to reach about 1/4" from the top. Holding the spline in place, roll the spline along the outside edge of the Spline Groove. When you get about 2" from the end of the Spline Channel, cut the spline about 1/4" short of the end of the Spline Channel. Roll to the end of the spline.

Screening : Top

Begin screening about 1" or 2" from the beginning of the spline channel. Pull the screening up lightly across the spline channel. Insert the spline to the inside of Spline Groove. Allow enough spline to reach about 1/4" from the start of the Spline Channel. Holding the spline in place, roll the spline along the outside edge of the Spline Groove. When you get about 2" from the end of the Spline Channel, cut the spline about 1/4" short of the end of the Spline Channel. Roll to the end of the spline.

Screening : Bottom

Begin screening about 1" or 2" from the beginning of the spline channel. Pull the screening down lightly across the spline channel. Insert the spline to the inside of Spline Groove. Allow enough spline to reach about 1/4" from the beginning of the Spline Channel. Holding the spline in place, roll the spline along the outside edge of the Spline Groove. When you get about 2" from the end of the Spline Channel, cut the spline about 1/4" short of the end of the Spline Channel. Roll to the end of the spline.

Trimming the Excess Screening Material

With a screw driver, push the ends of each piece of spline firmly in to place. Trim the excess Phiferglass© screening with a utility knife by pressing against the outer edge of the Spline Channel.

Loading... Please wait...

Loading... Please wait...